At the center of modern manufacturing, robot arms are changing the rules of production, mixing accuracy, safety and efficiency in ways that were unimaginable. These marvels of the mechanical realm, commonly referred to as robot arms, are essential in all industries and are driven by the imperative necessity to cut operating costs while maintaining high standards of quality. Integration of robotic arms in the production line allows manufacturers to not only reduce expenses but also improve work safety and efficiency. Find out how these machines have transformed the industrial landscape.

Image credit: automatedsolutions.com.au

Cost efficiency is the primary factor behind robotic arms’ global adoption. Factories face relentless pressure to limit production errors, reduce materials waste, and decrease incident rates in the workplace. Robotic arms are able to tackle these problems. Contrary to human laborers, robot arms perform repetitive tasks with pinpoint accuracy, eliminating costly mistakes and reducing raw material wastage. Robotic arms are utilized in high-volume industries for example, the automotive industry, to guarantee an exact assembly. This accuracy can result in significant savings since fewer imperfections result in less waste, rework and working.

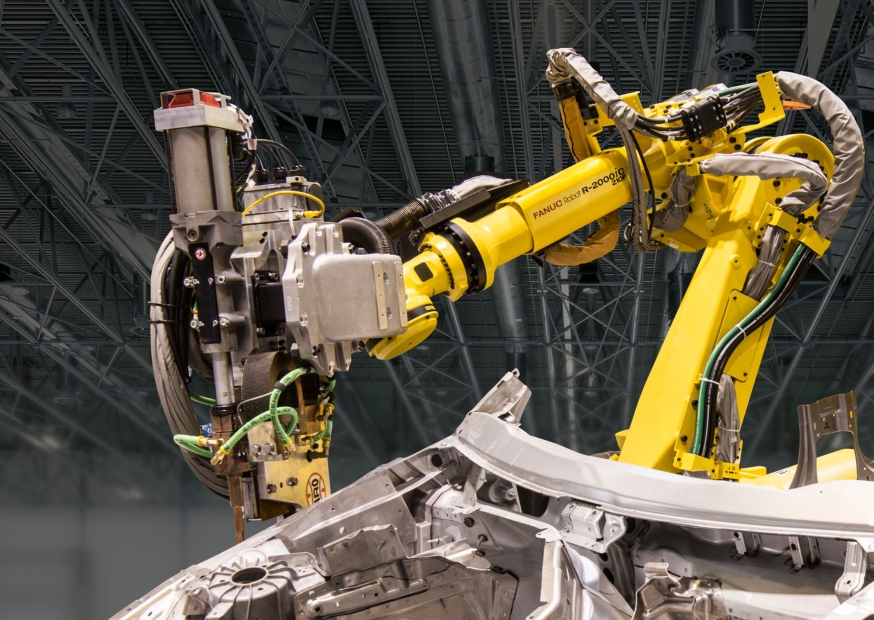

Safety is a second cornerstone in the revolution of robot arms. Human workers are at risk when performing many manufacturing tasks, such as handling dangerous materials or operating machinery that is heavy. Robot arms enable companies to keep their employees away from risky working environments and minimize workplace injuries. Robotic arms are made up of a variety of movable joints that mimic the human arm’s capabilities. But, they work without the danger of injuries. Equipped with hand end effectors, these machines are able to do tasks that are dangerous for humans, such as welding or spinning.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms can handle a variety of tasks. From assembly for automobiles to electronic production. The ability to program these arms enables them to carry out difficult tasks such as painting or applying fiberglass at an unmatched level of accuracy. Robotic arms in warehousing have revolutionized palletizing through the automation of loading of pallets with goods. The automation improves productivity as well as security because robot arms are able to work continuously without getting tired.

One of the most intriguing advancements in this field is the rise of collaborative robots, also known as cobots, that are able to work with human workers. Unlike traditional industrial robots confined to isolated cells, cobots equipped with robotic arms are engineered to ensure safe and seamless interactions with humans. In a workplace, a cobot’s robotic arm may be capable of handling difficult lifting or tasks that are repetitive, leaving humans to concentrate on more challenging tasks. Collaboration increases productivity and maintains a safe work environment, as cobots can be programmed to change or stop their movements if an individual is within.

The effect of robotic arms extends beyond safety and efficiency, to the very fabric of modern manufacturing. The capability of robotic arms to perform tasks with incredible precision including welding, material handling, or assembly is what makes them essential in industries where safety is the top priority. For instance, in the automotive manufacturing, a robotic arm is able to rotate and move parts while assembling, ensuring perfect alignment without human intervention. In electronics, robot arms handle delicate components with care, minimising damage and improving output quality.

Robotic arms are likely to gain importance as industries grow. They are a cornerstone for the future of manufacturing due to their capacity to cut costs, increase security, and adjust to various tasks. Through the combination of cutting-edge technology and human innovation, robot arms are not just tools they’re partners in advancement, bringing innovation to the forefront and revolutionizing the way we build our world.